Training High-Technology Equipment

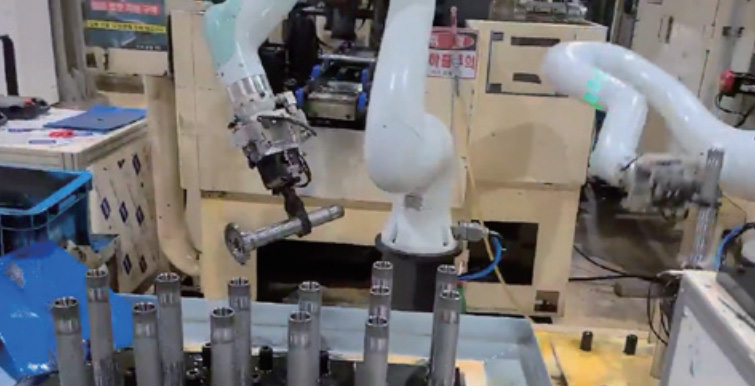

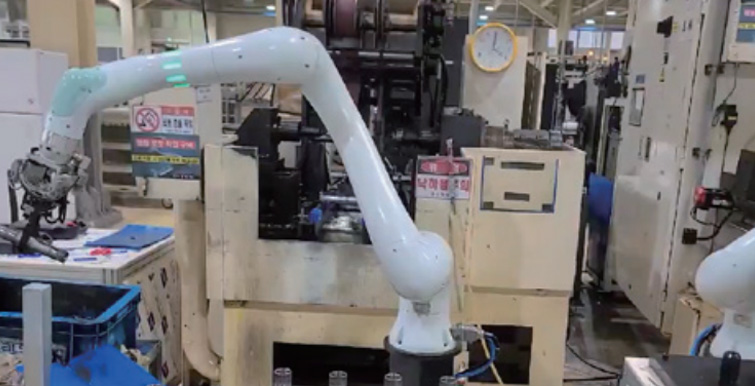

Automobile parts robot standard process

Key Delivery Performance

Key Delivery Performance

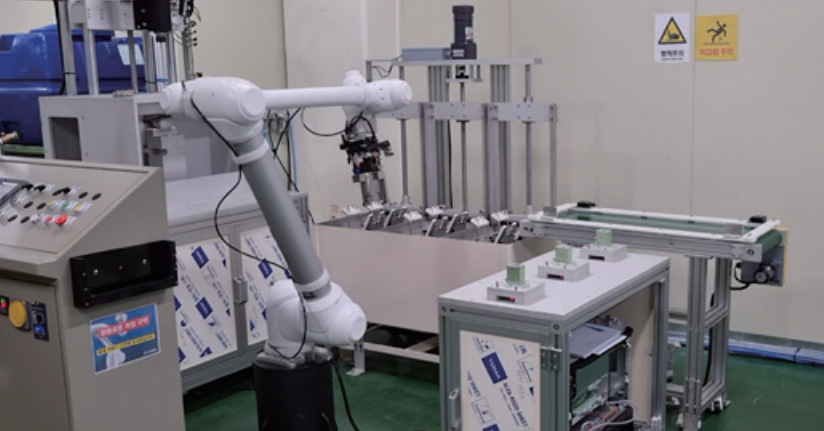

Automated weighing of automotive brake friction materials

|

Enterprise

|

Dion Automotive Co., Ltd.

|

|

Business Areas

|

Specialized production of brake pads

|

|

Process

|

|

|

Introduction effect

|

|

Before robot introduction

After introduction of robot

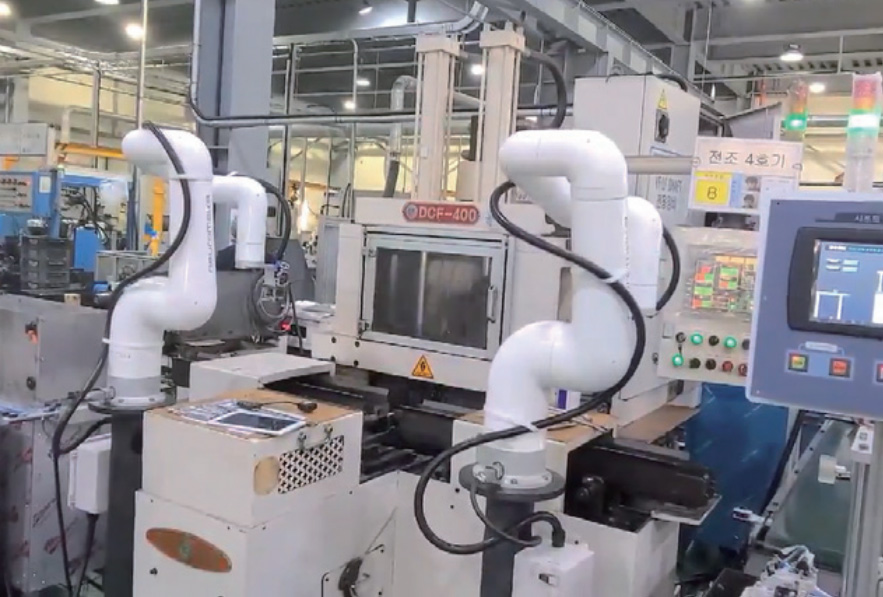

Automation of hydraulic fitting assembly (processing) dimensional inspection process

|

Enterprise

|

Dongbang Tech Co., Ltd.

|

|

Business Areas

|

CNC machining of hydraulic fittings

|

|

Process

|

|

|

Introduction effect

|

|

Inner Drum-Cluch polishing and mobile inspection process

|

Enterprise

|

Gisu Precision Co., Ltd.

|

|

Business Areas

|

Production of various shafts assembled in automobile transmissions

|

|

Process

|

|

|

Introduction effect

|

|

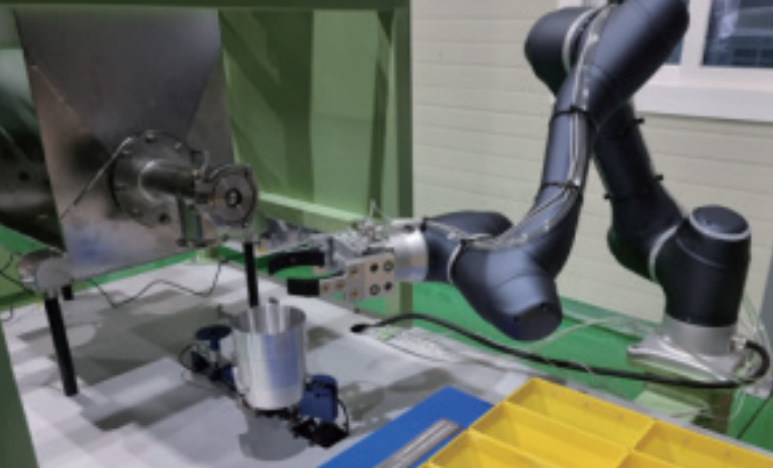

Automation of LPDI high pressure pump inner diameter polishing process

|

Enterprise

|

OMP Co., Ltd.

|

|

Business Areas

|

Aluminum/magnesium plasma electrolytic oxidation coating technology

|

|

Process

|

|

|

Introduction effect

|

|

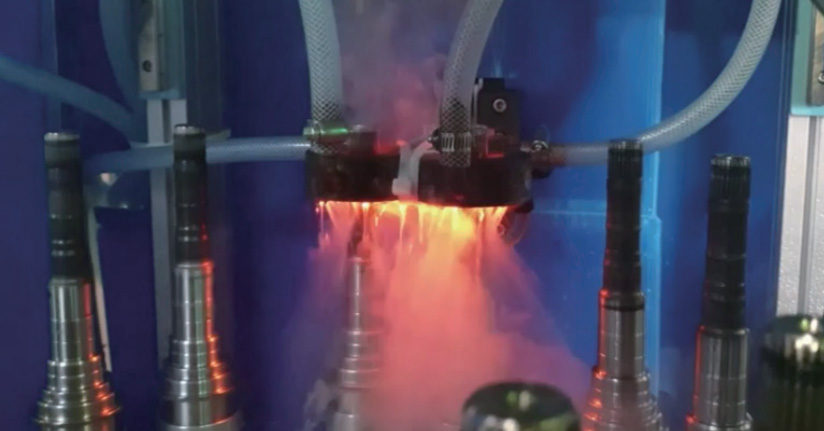

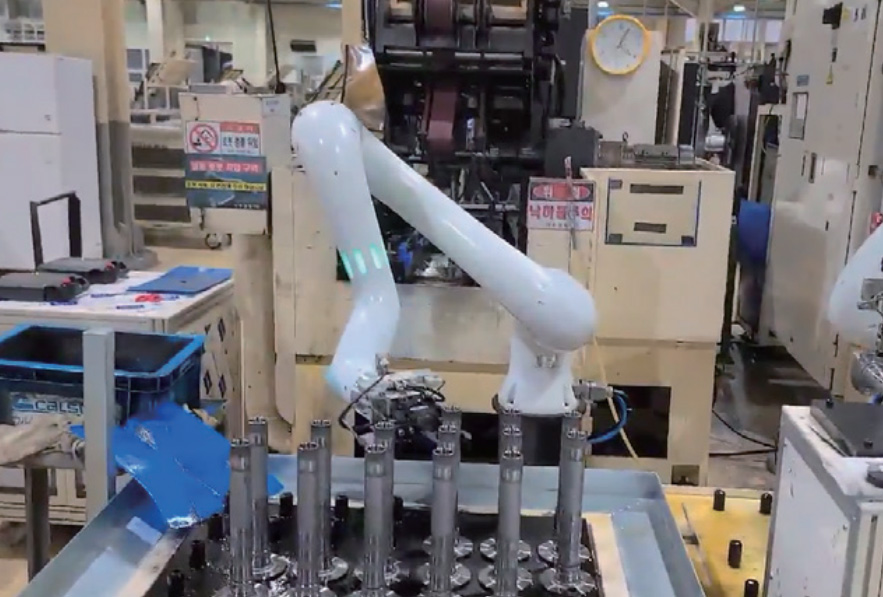

Automation of BALL Stud cleaning process and ECT mobile inspection process

|

Enterprise

|

Daesung General Heat Treatment Co., Ltd.

|

|

Business Areas

|

Specializing in high-frequency heat treatment, supplying vehicle parts to foreign automakers

|

|

Process

|

|

|

Introduction effect

|

|

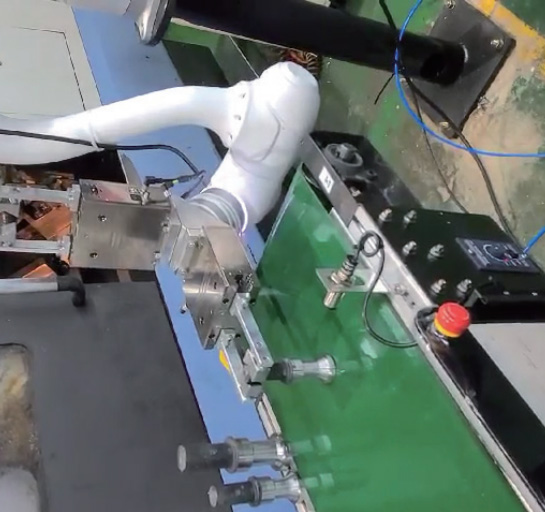

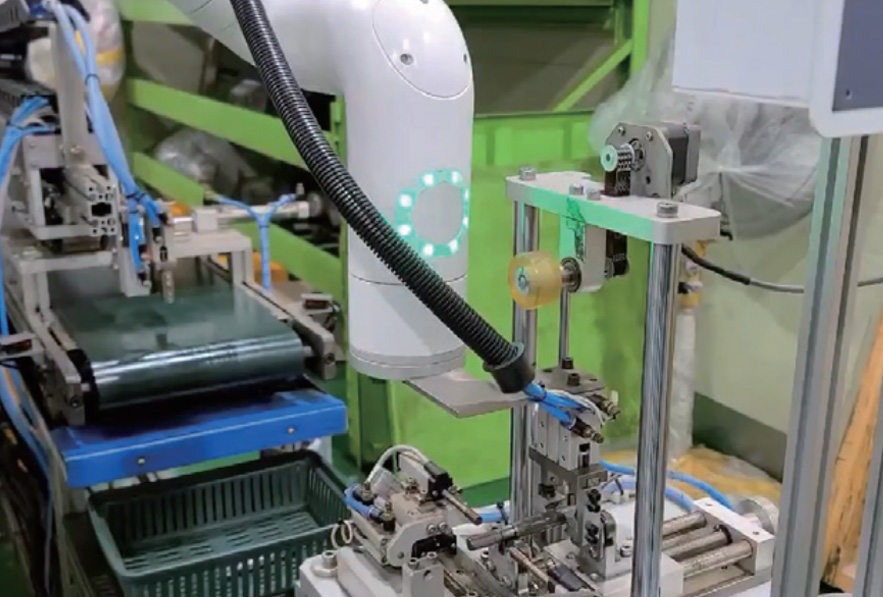

Automation of motor shaft rolling process and mobile inspection process

|

Enterprise

|

Cheongsu Precision

|

|

Business Areas

|

Machining of automobile motor shafts and MDPS motor shafts for electric steering systems

|

|

Process

|

|

|

Introduction effect

|

|

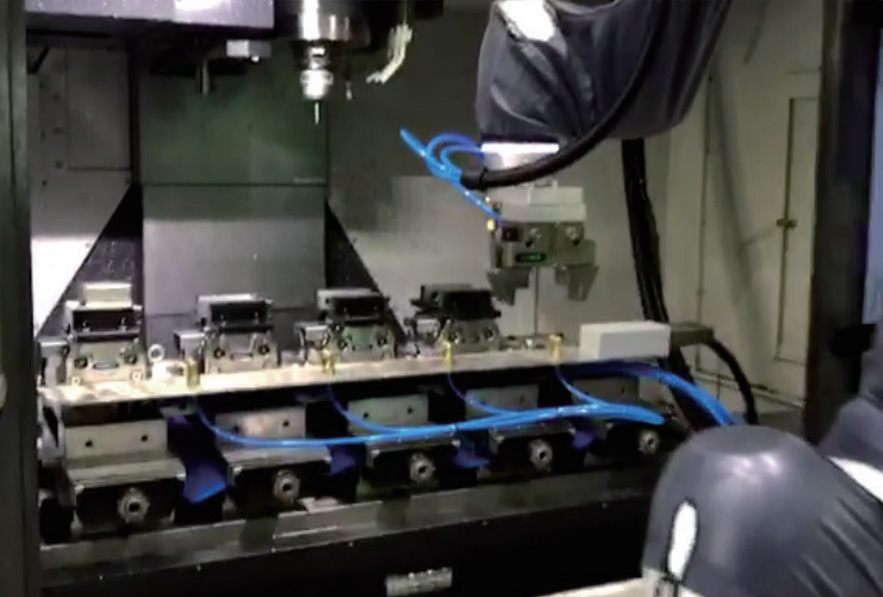

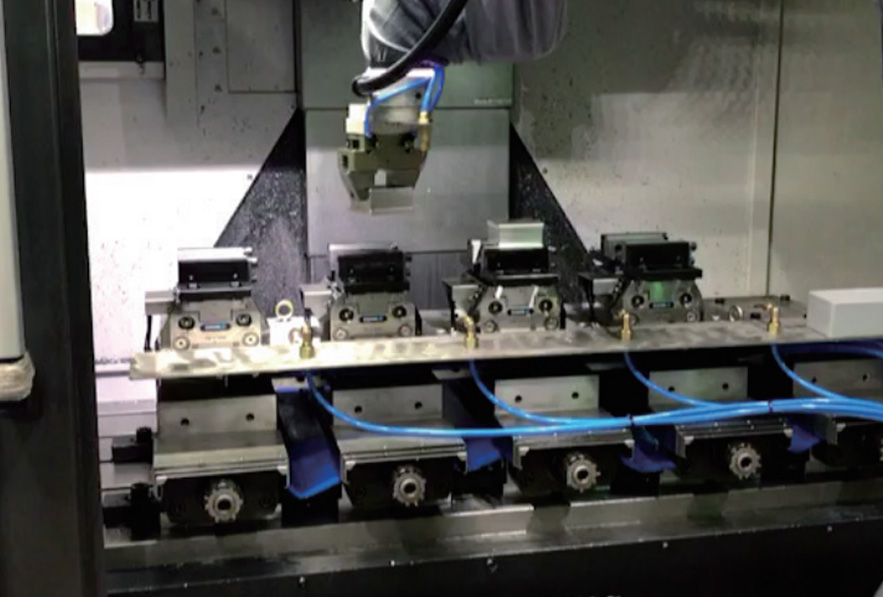

Automation of high pressure valve block MCT processing and inspection process

|

Enterprise

|

Hyflux Co., Ltd.

|

|

Business Areas

|

Toll processing of various parts including high-pressure valves used in the fuel system of hydrogen fuel cell vehicles

|

|

Process

|

|

|

Introduction effect

|

|