Training High-Technology Equipment

DCM for marine use

Control System

Control System

The Deep Cement Mixing Method (improvement work using DCM) involves injecting

a slurry mixture of cement and water under low pressure into weak ground. Simultaneously,

the weak soil and slurry are mixed and stirred by the rotation of a special agitator.

By utilizing cement and the curing reaction, the original ground is solidified,

forming a cylindrical solidified body to achieve ground stabilization.

This method is applied in various ways, including foundation work, embankment work,

and cut-off wall construction, with the aim of stabilizing the ground.

Major Systems

- Adjust equipment positioning GPS Positioning: Error ± 10 cm

- Excavation and Stirring Down Check the excavation speed: Within 0.3~1m/min (lumor layer,Reclamation layer)

- Check the support layer Judgment based on excavation speed and load amount

- Stirring up and down (4.0m) Check the rising speed: Within 0.3~1.0m/min (Slurry injection)

- Agitation rising atmosphere followed by lowering (5.0m) Alluvial agitation and lower discharge cleaning operations

- Rise by agitation (fill layer to sand layer) Confirmation of rise speed: Within 0.3~1m/min (Slurry injection)

- Agitation descent after reaching the sand layer (4.2m) Re-agitation operation for the expression of upper layer strength

- Wait for 5 minutes after rising 1m Upper cleaning operation of agitation bit

- Wait for 5 minutes after rising 2.2m Lower cleaning operation of agitation bit

- Rise to 0 point Move to the next construction location

The control unit of the steering room

Plant control unit

The steering room OP

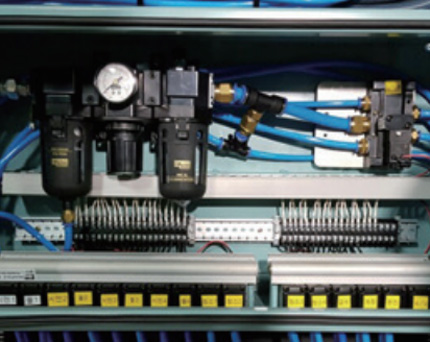

Cabinet Panel

Solenoid valve control

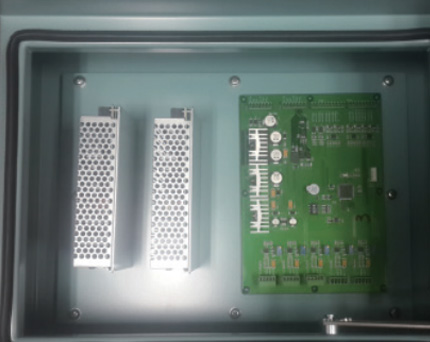

Department of DAU Communications

Measuring stirrer control

Flow sensor & measurement

Stirrer load cell & measurement

Key delivery performance and characteristics

- Construction of Hong Kong Airport Route 2, No. 7, 8, 9, and 11 for elementary stone construction

- Based on MEA2000 CAN communication in about 50 sensor module units, noise is strong and communication error rate is low

- Injection Timing can be automatically set up in the system without relying on the experience and skill of the worker

- Precise linear speed control with winch speed PID control, Submarine ground rock detection through wire treatment detection

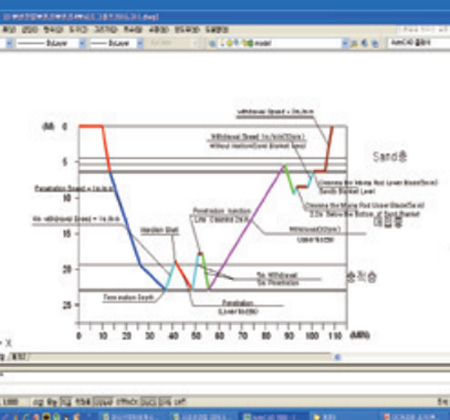

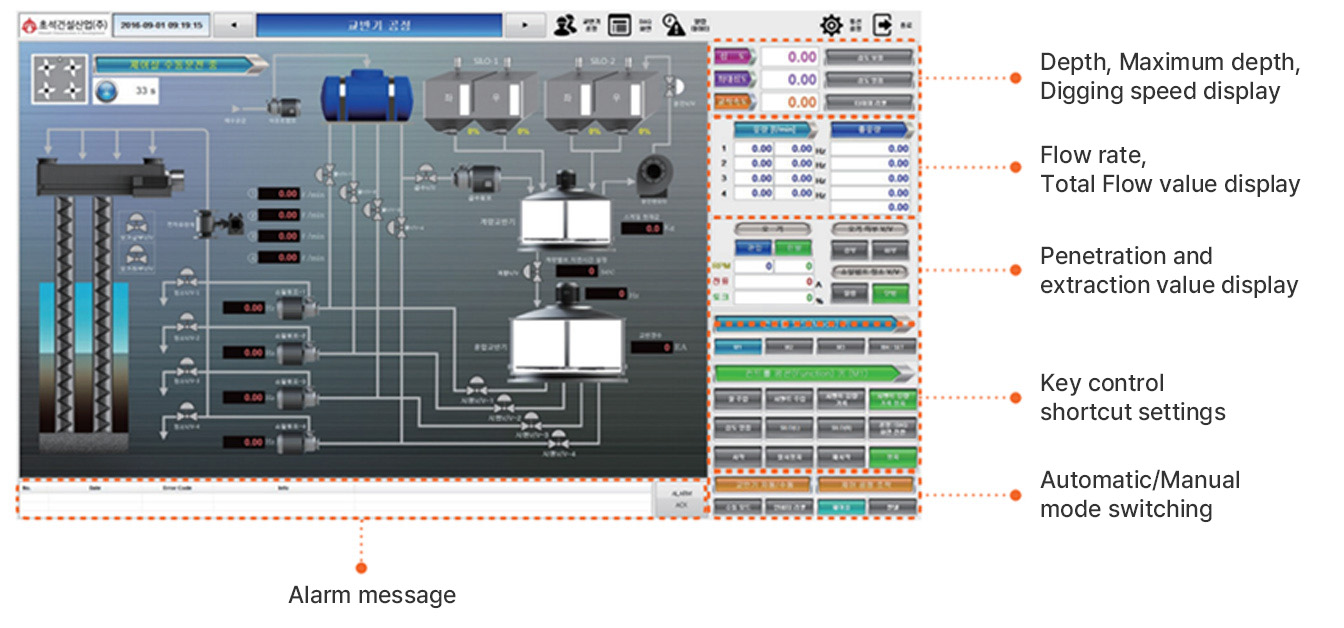

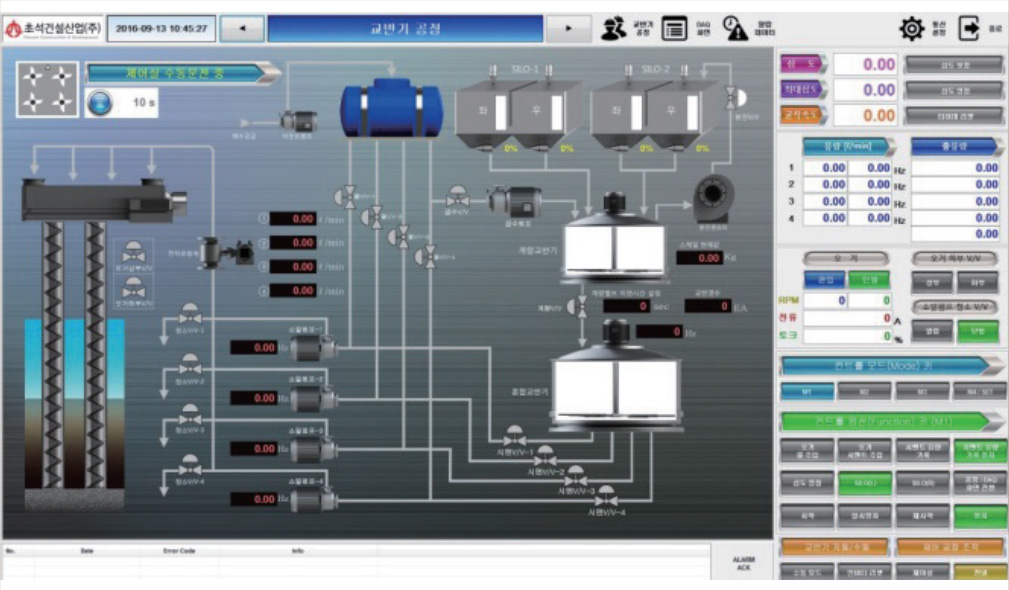

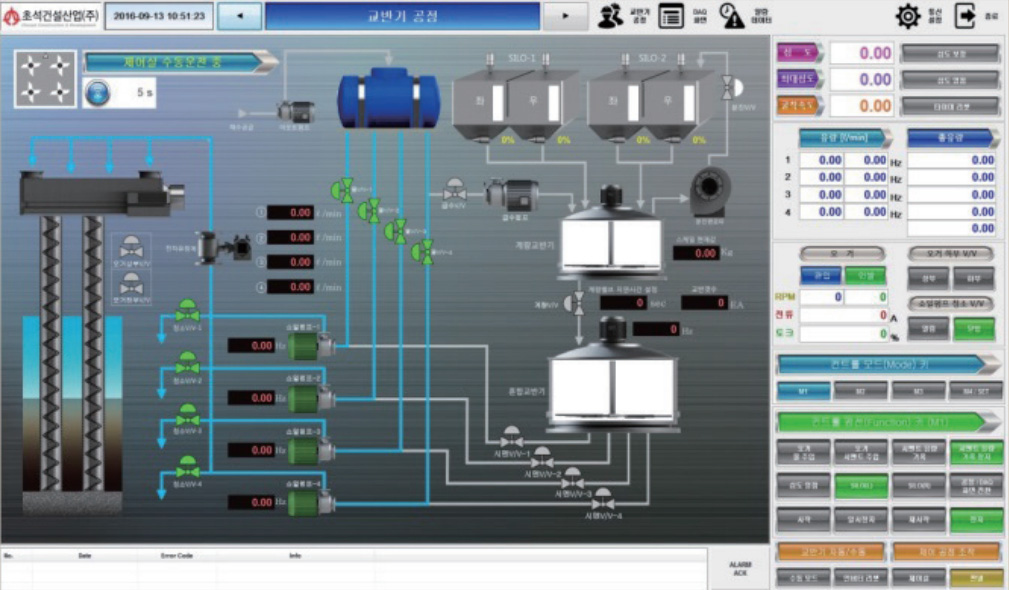

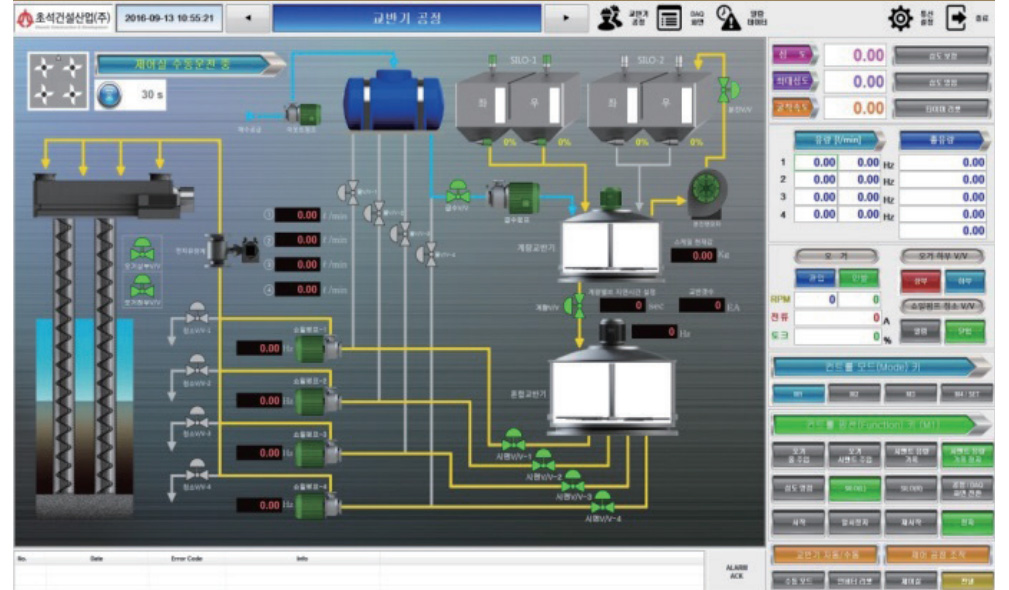

OP Main Control Screen

-

Main screen

- Monitor the overall system and group each control to make it more demonstrable than traditional systems

-

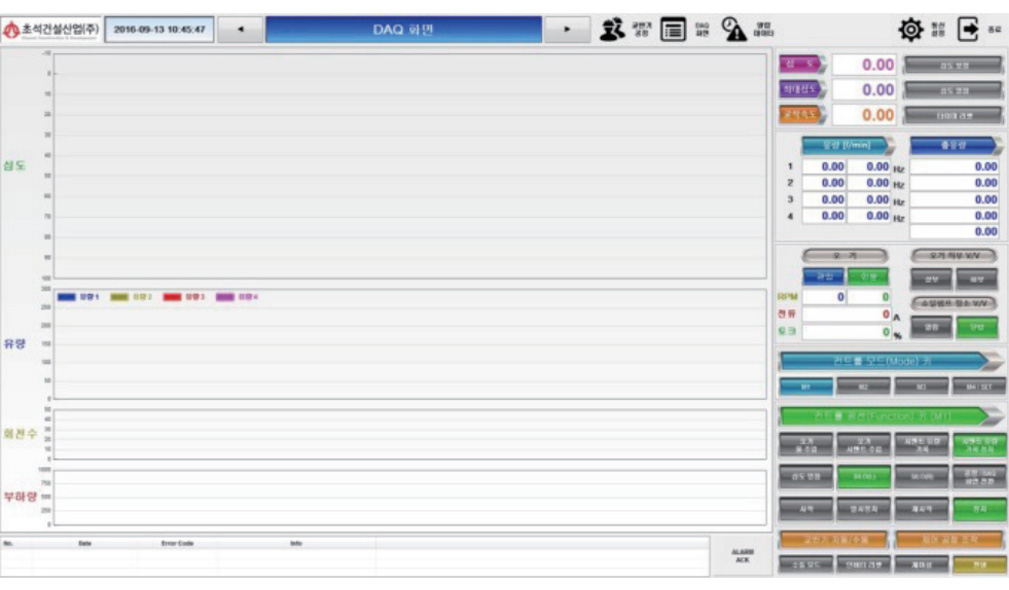

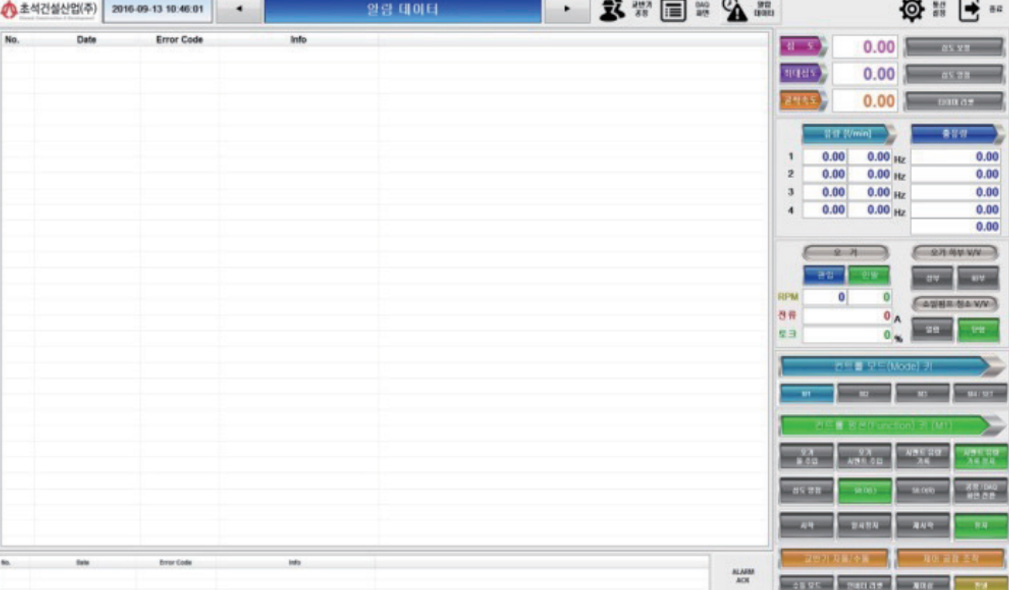

Monitoring Data

- By fixing important monitoring data that was used in the form of pop-ups in existing systems, important data can be viewed even when switching to another screen.

-

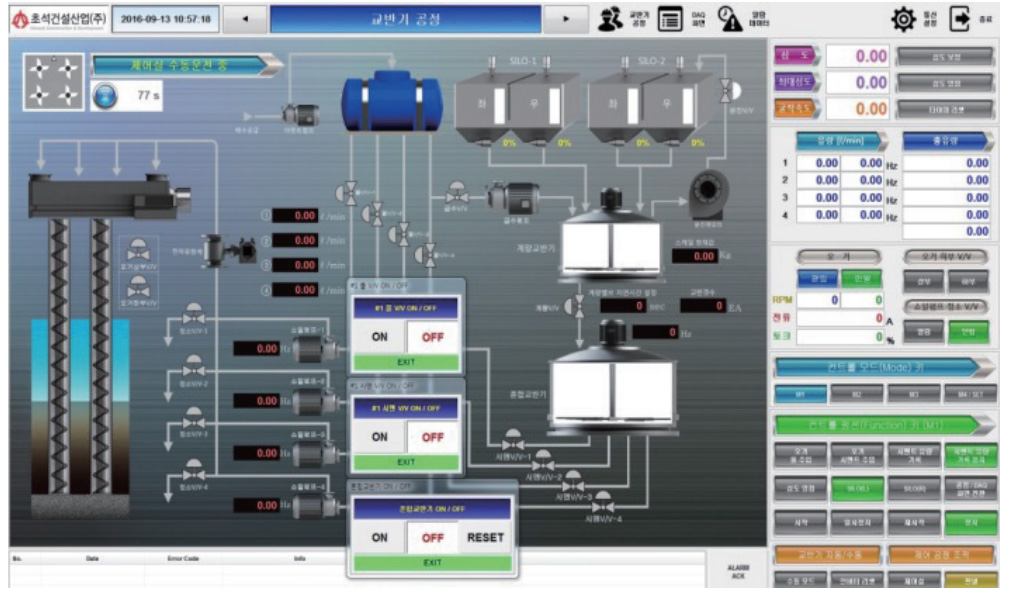

Setting key control shortcuts

- The method used to control using keyboard and mouse in the existing system has the convenience and scalability of shortcut function on keyboard using OP control key in the new system, and visual effect through real-time synchronization between OP panel and PC

OP Key Control Unit Design

Main screen

DAQ screen

Alarm data

Water injection screen

Cement injection screen

Motor/Pump Control Screen